Bending Baffle

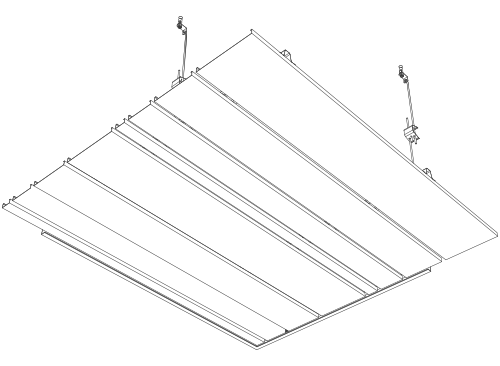

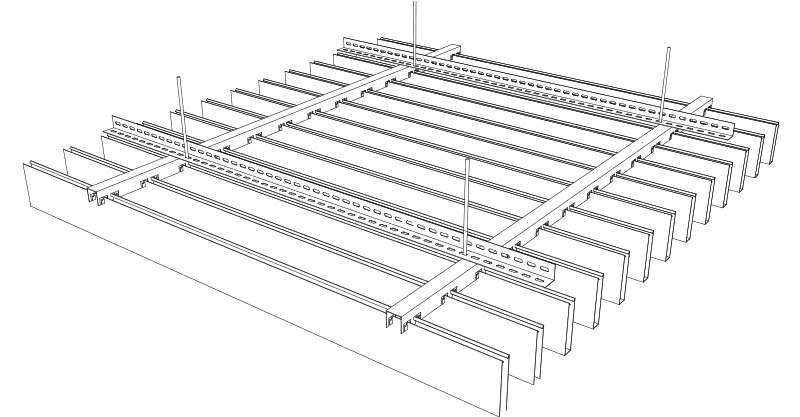

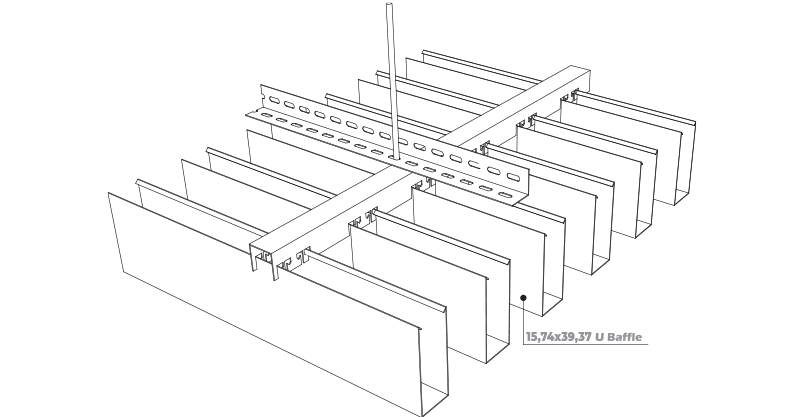

Baffle Ceiling System introduces a unique design element to any space and is a striking addition whether it is installed through-out an entire room or just serves as an accent. Both the style and spacing is customizable and the system can also be installed on either vertical or curved surfaces.

The Harlie Harper, baffle ceiling panels can be easily installed and uninstalled for accessibility. U-shape Aluminum Baffle Ceiling Systems is a decorative curtain-type ceiling, able to adjust the visual height of a house, and can hide all the pipelines and other facilities in the bottom of the building, and also can lead sunlight or lamplight.

It enables an open field of vision, good ventilation and airflow, the connection lines are bright and neat, with clear levels, reflecting the concise modern style, simple and convenient in installation assembly and dis-assembly, has become the main popular product on decoration market.

Baffle Ceilings create unique room atmospheres. These open ceiling constructions impress both with outstanding acoustics and the impressive possibilities of room layout. The free space between the baffles is optimally suitable for the integration of luminaires, sprinkler, ventilation systems or similar.

Baffle Ceilings are also suitable for belated installations to correct acoustical problems with concrete ceilings and to create a distinctive design.

Characteristics:

Original arrays arrangement and protean modeling. Ventilation, light transmission, ceiling facilities screen and deco- ration.

Convenient installation and independent dismantlement. Extraordinary in keeping away fires, moisture and corrosion. Free selections in thickness, shapes, intervals and colors.

In the world of engineering and manufacturing, the quest for optimal efficiency and performance is never-ending. One crucial element in various industries is the effective management of airflow and sound. This is where bending baffles come into play. In this article, we will delve into the concept of bending baffles, explore their benefits, applications, and shed light on why they are gaining prominence in New Jersey and beyond.

As industrial processes become more complex, finding innovative solutions to enhance efficiency and optimize performance has become paramount. Bending baffles, also known as curved baffles, are ingenious devices that contribute to improved airflow control and enhanced acoustic performance in various applications. Whether in HVAC systems, automotive manufacturing, or industrial processes, bending baffles offer numerous advantages that make them a sought-after solution.

Before diving into the specifics of bending baffles, let’s briefly discuss the concept of baffles. A baffle is a device or structure designed to alter the flow of a fluid or direct sound waves. It can be a solid or perforated barrier, strategically positioned to control the movement of air, water, or sound within a system. Baffles are widely used in various industries, including aerospace, automotive, construction, and more.

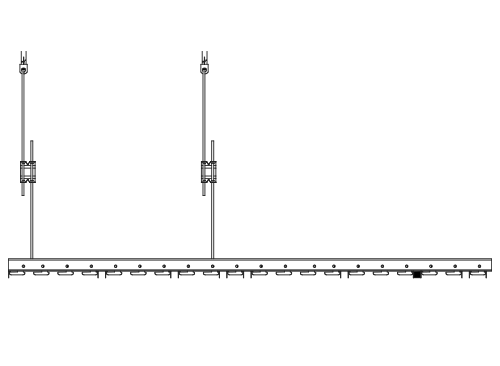

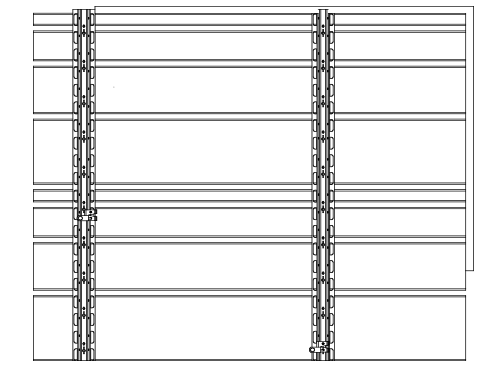

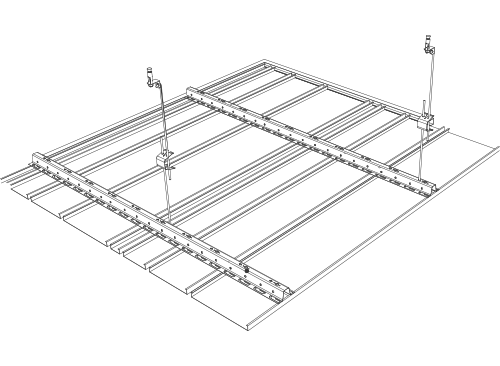

Multi Panel System

Introducing our Maintenance-Free Modular Multipanel System—a design innovation that not only captivates with its aesthetic versatility but also stands out as a hassle-free solution for modern spaces. Experience the perfect blend of form and function without the worry of time-consuming upkeep. Our Multipanel System is designed with a modular approach, allowing you to easily customize and reconfigure your space with minimal effort. Create dynamic layouts, experiment with patterns, and adapt your environment to evolving needs—all while maintaining a sleek and contemporary aesthetic. Say goodbye to the burden of regular maintenance. The durable materials used in our Multipanel System ensure longevity and resilience, requiring minimal attention to keep your space looking flawless. Enjoy the benefits of a stunning design that remains pristine with little to no effort on your part. Whether you’re aiming for a cutting-edge, minimalist look or a bold and artistic statement, our Maintenance-Free Modular Multipanel System empowers you to design with freedom. Elevate your space effortlessly, knowing that your investment in style comes with the added convenience of a maintenance-free solution.

Panel Size :

FMX-1 35; 35x4000x0.50mm

FMX-1 85; 85x4000x0.50mm

FMX-1 135; 135x4000x0.50mm

FMX-1 185; 185x4000x0.50mm

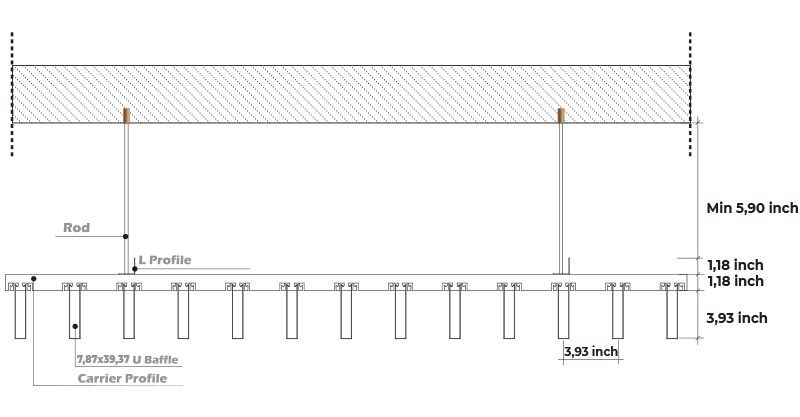

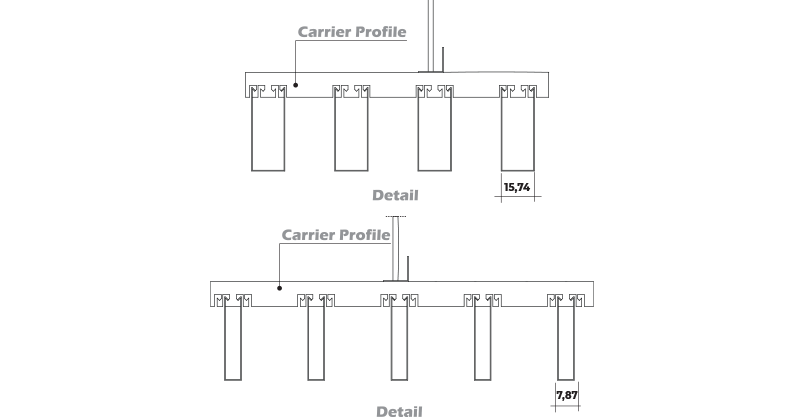

Technic Details

Baffles in HVAC Systems

In heating, ventilation, and air conditioning (HVAC) systems, baffles are utilized to regulate the flow of air within ductwork. By strategically placing baffles, engineers can control the distribution of conditioned air, ensuring optimal airflow and temperature control throughout the building. Baffles also help minimize pressure imbalances and prevent unwanted noise propagation.

Baffles in Industrial Processes

In industrial settings, effective airflow management is crucial to maintain process efficiency and product quality. Baffles are employed to control the direction and velocity of air within equipment and production lines. By optimizing airflow patterns, baffles contribute to improved heat transfer, reduced energy consumption, and enhanced process control.

Bending baffles have emerged as a valuable solution for enhancing airflow control and acoustic performance in various industries. Their curved design offers improved efficiency, reduced noise levels, and increased process optimization. Whether in HVAC systems, automotive manufacturing, or industrial processes, bending baffles have proven to be a reliable and effective choice.

With the ability to optimize airflow dynamics, improve acoustic performance, and offer customization options, bending baffles have become increasingly popular in New Jersey and beyond. As industries strive for better efficiency, energy savings, and a quieter environment, the utilization of bending baffles provides an innovative solution.

Incorporating bending baffles into HVAC systems, automotive applications, and manufacturing processes can lead to improved performance, enhanced productivity, and a more comfortable and sustainable working environment.

Applications of Bending Baffles

Bending baffles find wide-ranging applications in various industries. Let’s explore a few sectors where their utilization can make a significant difference.

HVAC Systems

In the realm of heating, ventilation, and air conditioning, bending baffles offer immense value. They can be incorporated into ductwork systems to improve airflow distribution, temperature control, and overall HVAC efficiency. By ensuring a balanced and optimized airflow, bending baffles contribute to better indoor air quality and comfort.

Automotive Industry

The automotive sector can benefit from the utilization of bending baffles in several ways. These curved devices can be used in air intake systems to regulate airflow, improving engine performance and fuel efficiency. Bending baffles also find applications in vehicle exhaust systems, aiding in noise reduction and emission control.

Manufacturing Processes

Industrial processes, such as chemical production, metal fabrication, and electronics manufacturing, rely on efficient airflow management for optimal results. Bending baffles can be integrated into equipment, such as heat exchangers and drying ovens, to enhance heat transfer, control temperature gradients, and ensure uniform product quality. Their use can result in improved process efficiency, reduced cycle times, and cost savings.

Bending baffles take the concept of traditional baffles a step further by introducing a curved design. Instead of using straight barriers, bending baffles feature curved surfaces that offer distinct advantages in terms of airflow control and acoustic performance.

The curvature of bending baffles allows for more efficient redirection of airflow. As air passes through the curved surface, it experiences less resistance, resulting in improved airflow dynamics. This enhanced airflow can contribute to better ventilation, reduced pressure drops, and increased energy efficiency in HVAC systems and industrial processes.

Additionally, bending baffles excel in managing acoustic properties. The curved design helps to disrupt sound waves and prevent their direct transmission. This reduces the propagation of noise and enhances the overall acoustic performance of a system or space. By effectively controlling sound transmission, bending baffles contribute to a quieter and more comfortable environment.

Bending baffles improve airflow in HVAC systems by minimizing turbulence and pressure drops. The curved design allows for smoother air movement, optimizing ventilation and ensuring consistent air distribution throughout the system.

Yes, bending baffles offer customization options to fit specific requirements. The curvature, dimensions, and placement of the baffles can be tailored to optimize airflow control and acoustic performance in different applications.

Yes, bending baffles can be manufactured using materials that are suitable for high-temperature applications. Metals like stainless steel and certain heat-resistant polymers can withstand elevated temperatures, making them ideal choices for such environments.

Common materials used for bending baffles include aluminum, stainless steel, and various polymers. The choice of material depends on factors such as corrosion resistance, thermal stability, and durability required for the specific application.

Yes, bending baffles are effective in reducing noise pollution in industrial settings. The curved surfaces of the baffles scatter and absorb sound waves, preventing their direct transmission and resulting in a quieter working environment.

Contact Us

For Business: Do you have questions about how Manufactory can help your company? Send us an email and we’ll get in touch shortly, or phone +1 646 270 89 83 between 09:00 and 17:00 Monday to Saturday — we would be delighted to speak.

Note: Your details are kept strictly confidential as per our Company Privacy Policy.