Opencell Ceiling

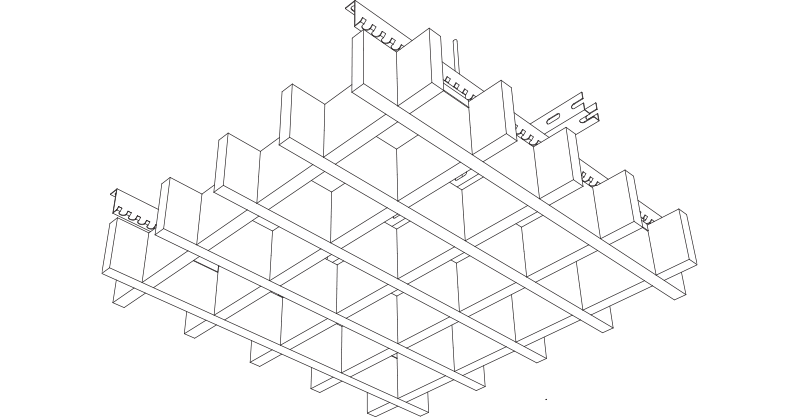

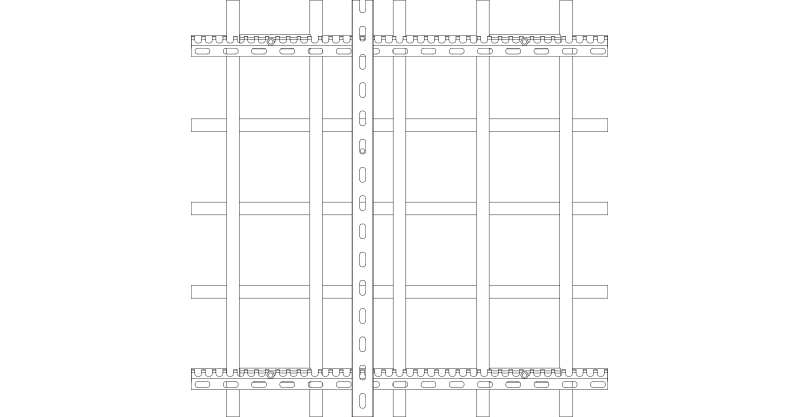

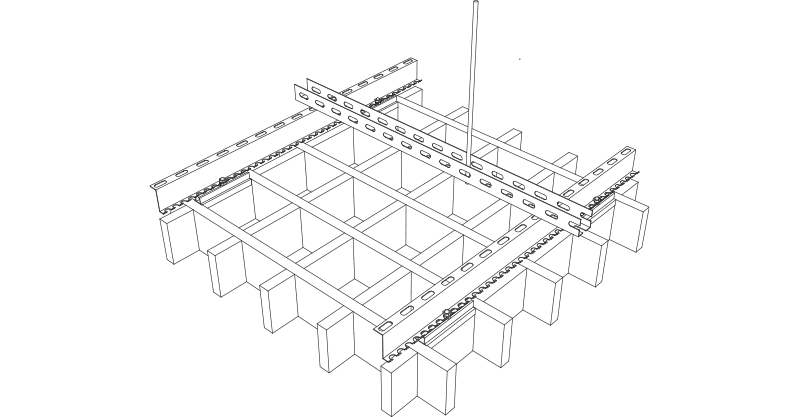

Continuous Cubes are cell-like assembled panels that fit into a wood grid system. Wood segments are suspended perpendicular to each other, interlocking vertically to create the cell-like structure. Continuous Cube panels are supported by a wood grid manufactured and supplied by Undo Ceiling from wood main runners and cross tees that match the cube panels in color and profile. The 23,62×23,63 inch panels drop into the wood grid assembly, creating a monolithic ceiling appearance. Standard cell sizes are available in 2,95 inch, 3,93 inch, 7,87 inchand 11,81 inchmodules. Standard cell depths are 0,39 inch, 0,78 inch, and 1,18 inch. Wood segments are 0,70 inchthick. Contin- wooden Cubes are available in solid wood or veneer.

WOOD SPECIES

Harlie Harper Ceiling Panel Grilles may be specified in a variety of wood species. Panel Grilles may be specified in a variety of wood types. Current standard wood species are Ash, Maple, Red Oak, White Oak, Beech, Poplar, and Cherry. Thermally modified wood species are also available. Standard veneer wood species are Ash, Maple, Walnut, Red Oak, White Oak, Anegre, Beech, Bamboo, and Cherry. Premium veneers and non-wood laminates are available

CONTINUOUS CUBES

Open, cell-like ceiling system with maximum yield open area to contribute to sound attenuation, plenum access, and simple MEP integration. Wood mains and cross-tees replace a standard grid system to provide an all-wood appearance.

MODULAR CUBES

Open, cell-like ceiling system with maximum yield open area to contribute to sound attenuation, plenum access, and simple MEP integration. Drop-in panels fit most standard grid systems, new installations or retrofit.

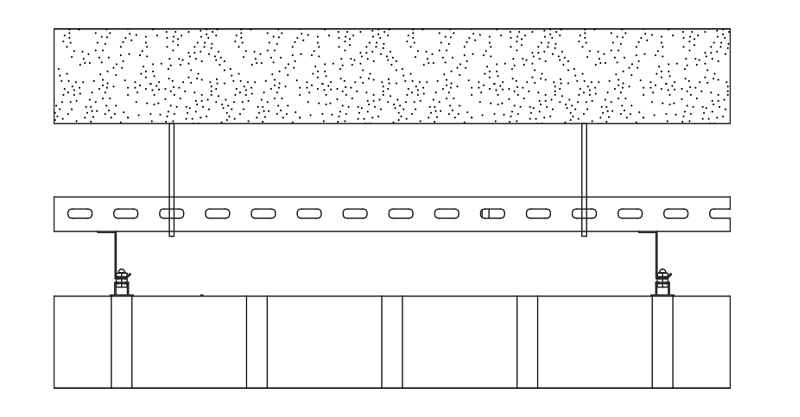

EASE OF INSTALLATION

Through the use of eye-screws and interconnected components or perimeter lay-in wood backer strips, Undo Ceiling Top panels are easy to install.

In an era of sustainable design and eco-friendly materials, wooden opencell has emerged as a remarkable solution that combines functionality and aesthetics. With its unique cellular structure, wooden opencell offers an innovative approach to architectural design, providing a range of benefits and applications. This article explores the world of wooden opencell, its advantages, applications, installation, and maintenance, while also delving into its environmental considerations, technological advancements, and future trends.

Wooden opencell, also known as open-cell wood or open-cell timber, refers to a specialized type of wood product that features an interconnected network of cells. These cells are purposely created during the manufacturing process, resulting in a visually appealing material that allows air, light, and sound to pass through. The opencell structure enhances the natural beauty of wood, providing a unique visual and tactile experience.

Aluminum Open Cell Ceiling Panels

This alternative offers versatility and practicality, making it an attractive choice for projects where weight and budget considerations are key factors. The aluminum open cell panels, while maintaining the visual appeal of the wood-based system, bring a modern touch and durability to the table.

The lightweight nature of the aluminum panels simplifies installation and handling, reducing overall project costs and labor requirements. Additionally, the material’s inherent durability makes it suitable for a variety of environments, including spaces that may have higher moisture levels or require easier maintenance.

The introduction of this alternative not only expands the range of options but also allows for greater flexibility in choosing the most suitable material based on specific project needs. It’s an excellent example of how innovation and material selection can contribute to both aesthetic and practical considerations in architectural design.

Furthermore, with square and angle grids available, the customization options are further enhanced, offering architects and designers the freedom to play with diverse shapes and layouts. This additional feature adds another layer of adaptability to the already versatile system, ensuring it meets the unique requirements of each project.

Technic Details

Enhanced Aesthetics

Wooden opencell showcases the natural patterns, grains, and textures of wood, adding a touch of warmth and beauty to any space.Efficient Air Circulation

The open cells promote air movement, creating a natural ventilation system that enhances indoor air quality and thermal comfort.Improved Acoustic Performance

The cellular structure of wooden opencell helps to absorb and diffuse sound, reducing echo and improving acoustic quality.Softened Lighting Effects

The translucent properties of wooden opencell allow light to filter through, creating a soft, diffused glow that enhances the ambiance.

As sustainable design practices continue to gain momentum, the future of wooden opencell looks promising. The demand for eco-friendly materials and biophilic design solutions is expected to drive further innovation in this field. Architects and designers will likely explore novel applications, pushing the boundaries of what wooden opencell can achieve.

Technological advancements, such as the integration of smart sensors and automation, may offer exciting possibilities for adaptive opencell systems that respond to changing environmental conditions. Additionally, the development of more efficient manufacturing processes and the exploration of new wood species will contribute to expanding the range of choices available to design professionals.

Wooden opencell is a captivating and sustainable solution that brings the beauty of nature into architectural design. Its unique cellular structure offers a host of benefits, from enhanced aesthetics to improved acoustics and natural ventilation. With its diverse applications, ease of installation, and minimal maintenance requirements, wooden opencell presents a compelling option for designers seeking both functionality and visual appeal.

As advancements in technology continue to unlock new possibilities, the future of wooden opencell holds even greater potential. By incorporating this innovative material into architectural projects, we can create harmonious spaces that connect with nature, improve indoor environments, and contribute to a sustainable future.

Wooden opencell continues to evolve with advancements in technology and design. Innovations have led to the development of new manufacturing techniques, allowing for greater customization, improved precision, and enhanced durability. Manufacturers are exploring various wood species, cell configurations, and finishes to expand the range of possibilities and cater to diverse design preferences.

Digital fabrication and parametric design tools have also contributed to pushing the boundaries of wooden opencell, enabling intricate patterns, complex geometries, and seamless integration with other architectural elements. These advancements open up new avenues for creative expression and offer architects and designers the flexibility to realize their vision.

Case Studies and Success Stories

Numerous projects have embraced the beauty and functionality of wooden opencell, leaving their mark on the architectural landscape. From high-end residential developments to commercial and public spaces, the versatility of wooden opencell has been demonstrated in various contexts.

One notable example is the “Cellwood Pavilion,” an iconic structure that showcases the potential of wooden opencell. Located in a public park, the pavilion features a striking facade made entirely of opencell wood, allowing visitors to experience the interplay of light, shadow, and natural ventilation. This project exemplifies the seamless integration of nature-inspired design and sustainable materials.

Yes, wooden opencell can be used in exterior applications. However, it is important to choose a wood species that is suitable for outdoor use and to apply appropriate finishes or treatments to enhance its durability and weather resistance.

Wooden opencell can be treated with fire-resistant coatings to enhance its fire resistance. However, it is crucial to consult with professionals and ensure that the specific product and treatment meet the required fire safety standards for your project.

Yes, wooden opencell can be customized to fit specific design requirements. Manufacturers often offer a range of options for wood species, cell configurations, sizes, and finishes, allowing for tailored solutions that align with the design vision.

Wooden opencell contributes to sustainable design by utilizing a natural and renewable material. Wood is a carbon-neutral material that stores carbon throughout its lifecycle, making it an environmentally friendly choice. Additionally, sourcing wood from responsibly managed forests ensures the preservation of biodiversity and supports sustainable forestry practices.

Yes, wooden opencell can be combined with other materials to create unique design compositions. It can be integrated with glass, metal, or concrete, among other materials, to add depth, contrast, and visual interest to architectural projects.

Contact Us

For Business: Do you have questions about how Manufactory can help your company? Send us an email and we’ll get in touch shortly, or phone +1 646 270 89 83 between 09:00 and 17:00 Monday to Saturday — we would be delighted to speak.

Note: Your details are kept strictly confidential as per our Company Privacy Policy.